Color paste of plant-derived resin

with brilliant color development

Grease with unique gloss and adhesion is made by melting the resin of Candelilla to low polarity oil. COLOR GREASE, which we introduce in this page, is color paste mixed of the grease and pigment. It has more brilliant color development than other color paste, and its pigment and its oil do not separate even stored for a long time. Therefore, you can utilize it very easily.

Having high water resistance and

preventing bleeding to water

In COLOR GREASE, pigment gathers around the resin, and the low polarity oil wraps them. The oil functions as barrier and prevents the pigment from touching water, and therefore the bleeding phenomenon is difficult to happen. Making a good use of it, you could create a lipstick without color bleeding.

COLOR GREASE

INCI Name: Euphorbia Cerifera (Candelilla) Wax Extract,

Squalane, Others

COLOR GREASE is color paste mixed of the resin of Candelilla, squalane, and pigment. It has brilliant color development, and the squalane and the pigment do not separate even stored for a long time. In COLOR GREASE, the pigment gathers around the resin, and the squalane wraps them. Therefore, the suqualane functions as barrier and prevents the pigment from bleeding to water. Making a good use of it, you could create a lipstick without color bleeding.

Product name: COLOR GREASE

INCI name: Euphorbia Cerifera (Candelilla) Wax Extract,

Squalane,

Others

Net weight: 5 kg

Color variation: 10 colors

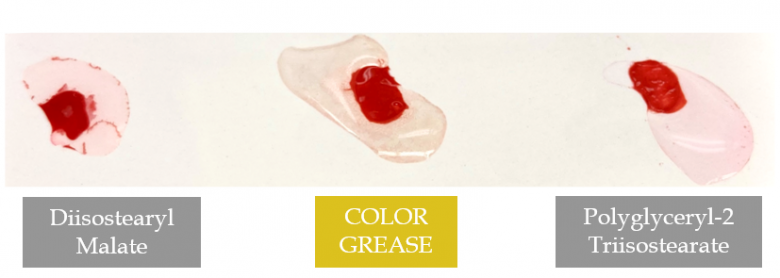

(Upper) We compared color development of COLOR GREASE and the other color pastes (Polyglyceryl-2 Triisostearete and Diisostearyl Malate). This picture indicates that COLOR GREASE has the most brilliant color developing of the three even in each color, in each color.

(Middle) We left the color pastes and compared their state. This picture indicates that the pigment and the oil separate in Polyglyceryl-2 Triisostearete and Diisostearyl Malate, but on the other hand the separation does not happen in COLOR GREASE.

(Lower) We dropped water to liquid rouges with each color paste, left them for two hours, and compared their state. This picture indicates that the pigment bleeds to water in Polyglyceryl-2 Triisostearete and Diisostearyl Malate, but on the other hand the bleeding does not happen in COLOR GREASE.

【Color Variation】

We are able to produce COLOR GREASE with pigments not only listed in this page but also you want (Net weight: 5 kg).

COLOR GREASE TDO

60% Titanium Dioxide

(Pigment White 6, CI 77891)

COLOR GREASE BIO

55% Iron Oxide of Black

(Pigment Black 11, CI 77499)

COLOR GREASE RIO

60% Iron Oxide of Red

(Pigment Red 101, CI 7749)

COLOR GREASE YIO

40% Iron Oxide of Yellow

(Pigment Yellow 42, CI 77492)

COLOR GREASE B1AL

40% FD&C Blue No.1

(Food Blue 2, CI 42090)

COLOR GREASE R28AL

40% D&C Red No.28

(Acid Red 92, CI 45410)

COLOR GREASE R6NA

35% D&C Red No.6

(Pigment Red 57, CI 15850)

COLOR GREASE R7CA

45% D&C Red No.7

(Pigment Red 57:1, CI 15850:1)

COLOR GREASE Y5AL

40% FD&C Yellow No.5

(Acid Yellow 23, CI 19140)

COLOR GREASE Y6AL

40% FD&C Yellow No.6

(Food Yellow 3, CI 15985)